Parts

& Inventory, Overview:

Automation Premium has the ability to sell parts as catalogue or inventory

items. Catalogue items have no stock control and as such no record flows

through to quantity on hand., The cost price for catalogue items can be

edited from the parts listing, job card or invoice. Cost and retail for

non-inventory items (catalogue) are posted to cost of goods sold, income

and an other current assets account titled non-inventory purchases.

It

is suggested the operator take full advantage of the powerful inventory

management functions of Automation Premium which including category management,

stock take reporting by category or location. To ensure inventory management

is a breeze we have included pricing and inventory management utilities

that allow for global price changes and automatic conversion of catalogue

items to inventory.

This

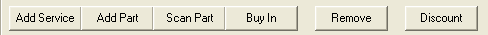

chapter also explains how you can save time by attaching a key board wedge

scanner giving you the ability to scan barcodes and enter items straight

to the invoice or job card without touching the keyboard.

Parts

Listing, Searching:

The

default search field is part number, if you wish to search by this field

type your query into the search field, the cursor will move to the record.

It is also possible to search by any field in the listing, to change the

search simply point at the header record and select the text will change

to blue indicating a change of search field. You can search the

list by keyword, for instance locating an item containing the word wiper

in the part field requires entry to the search field, selecting the double

arrows to the right of the search field will scroll through all part description

containing the word wiper regardless of position.

Parts

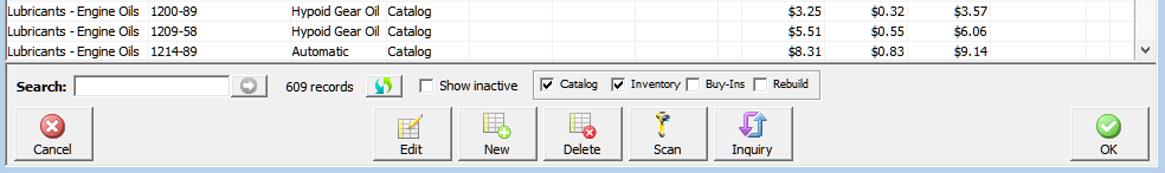

Listing, Searching By Barcode:

To

search by barcode select scan from the bottom of the screen, the scan

entry field is displayed, scan the part required and the cursor will locate

the item.

Parts

Listing, Filtering:

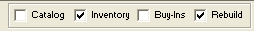

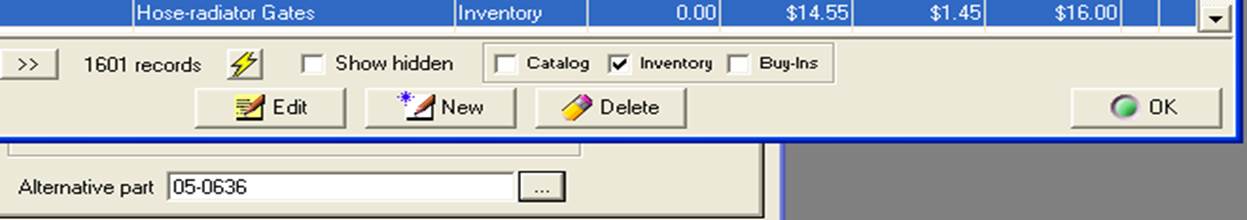

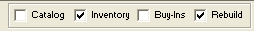

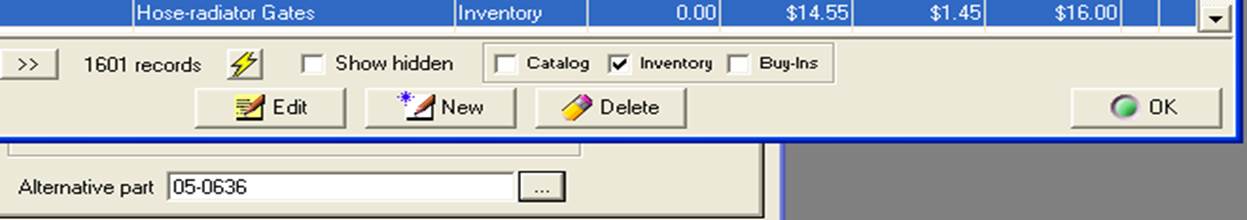

Selecting the check boxes at the bottom of the display window to view

catalogue, inventory or buy-ins.

Category

Management:

Categories

and sub categories can be setup by selecting lists / categories. It is

good practice to add a category to each inventory, catalogue or service

item as many functions and reports within Automation are category based.

For instance adding a category to an item gives the operator an opportunity

to track sales and profitability for a defined group of parts or perform

a stock take by single or multiple categories.

Category

Management, Adding New Categories:

From

the top of the screen select lists / categories, or view from the part

and services form. Select new from the bottom of the list, your category

form is now in view. To enter a new category or sub category type your

entry into the category field i.e.: Batteries, spark plugs, electrical

etc. It is also possible to create sub categories, for instance you may

stock two types of batteries Exide and Century if you wish to track sales

and run re-order reports by supplier setup two sub categories by attaching

the Exide and Century entries to the master category batteries. Select

parts, services or supplier as a grouping.

Category

Management, Deleting Categories:

The

system will not allow you to delete categories that have been assigned

to items by selecting the delete function at the bottom of the listing.

However if you wish to not list a category it can be hidden from view

by selecting the hidden option on the category form. Essentially this

option retains the category for data integrity purposes even though it

can no longer be accessed from the main screen

Default

Markup, Setting:

Automation allows you to set a default markup for parts by category, the

default markup can then be applied to the part form automatically calculating

a standard retail bases on cost price or the recommended Repco retail

price. To activate this feature perform the following:

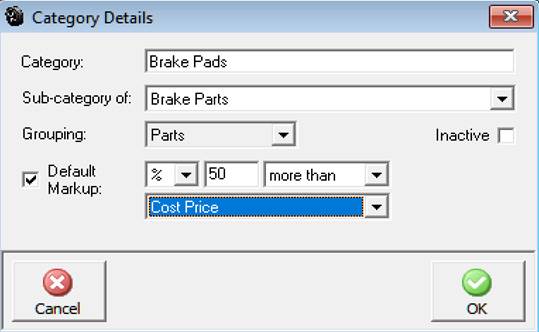

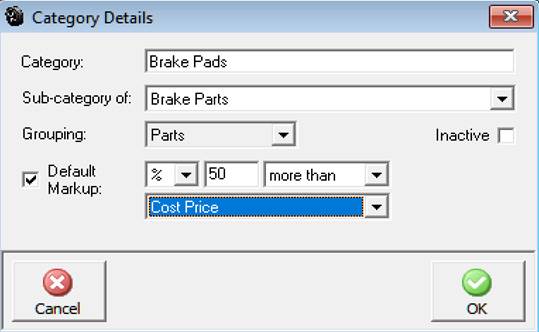

1) Open

the category listing by selecting lists from the top of the screen

point and click on the category option in the drop down menu.

2) Point

and double click on the category you

wish to set the markup for, the category detail form is displayed.

3) Point

and click on the default markup checkbox, you can now enter values

into the corresponding fields.

4) Select

the arrow to the right of the first field, select the $ or %

sign, enter the value into the next field, click on the arrow of

the third field, select more than or less than (less than should

only be used if setting by Repco RRP) finally select the calculation criteria

either Cost or Repco RRP, save with OK (F12).

Default

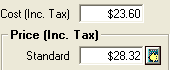

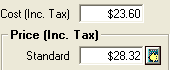

Markup, Applying To The Part Form:

If a markup has been set for a category attached to an item entered onto

the part form an arrow is visible next to the standard price field. To

calculate the sell price using the default markup enter your cost or Repco

RRP (into the appropriate field) next point and click on the arrow, the

sell price is automatically inserted.

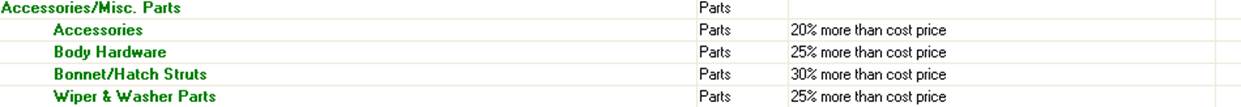

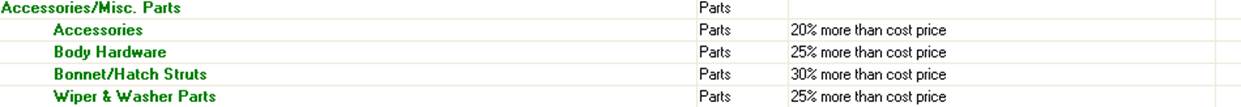

To

reference your markup settings go to the category list the value and calculation

criteria is displayed in the right hand column.

Catalogue

Parts, Creating:

To

create a new catalogue item open the parts listing and select new from

the bottom of the display. This action opens the part form which has three

tabulated choices details and purchasing and sales. Details contain the

item setup data, purchasing information including supplier and invoice

number, this choice does not apply to catalogue items as there is no purchasing

history. Sales detail the sales history including client and invoice number.

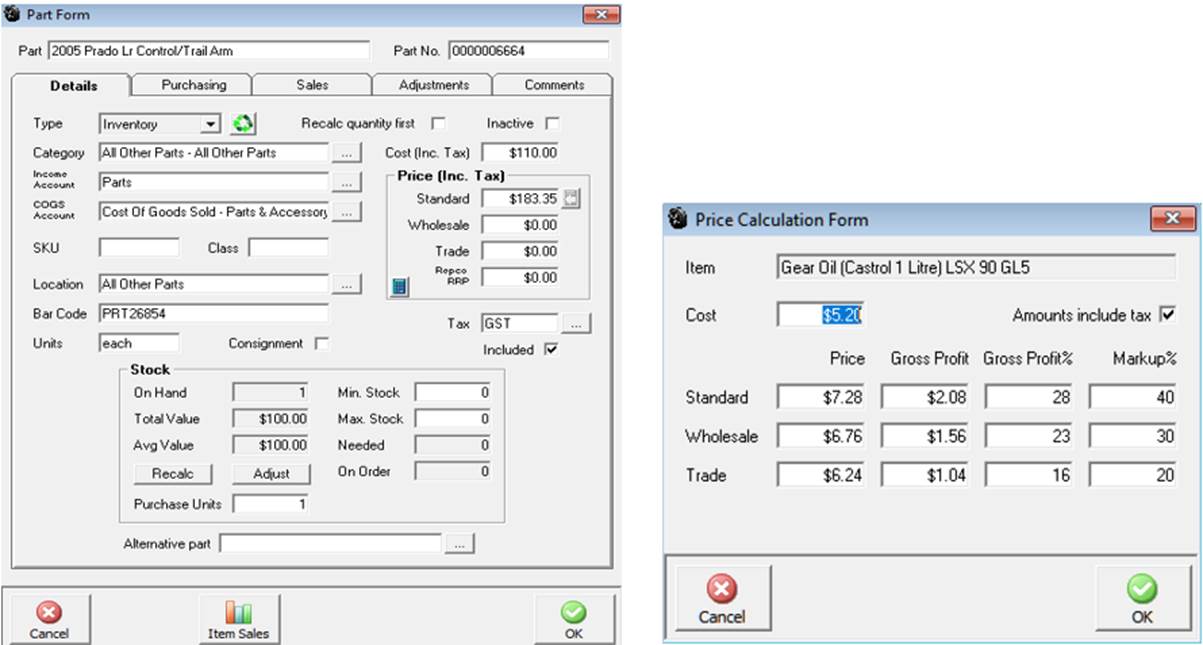

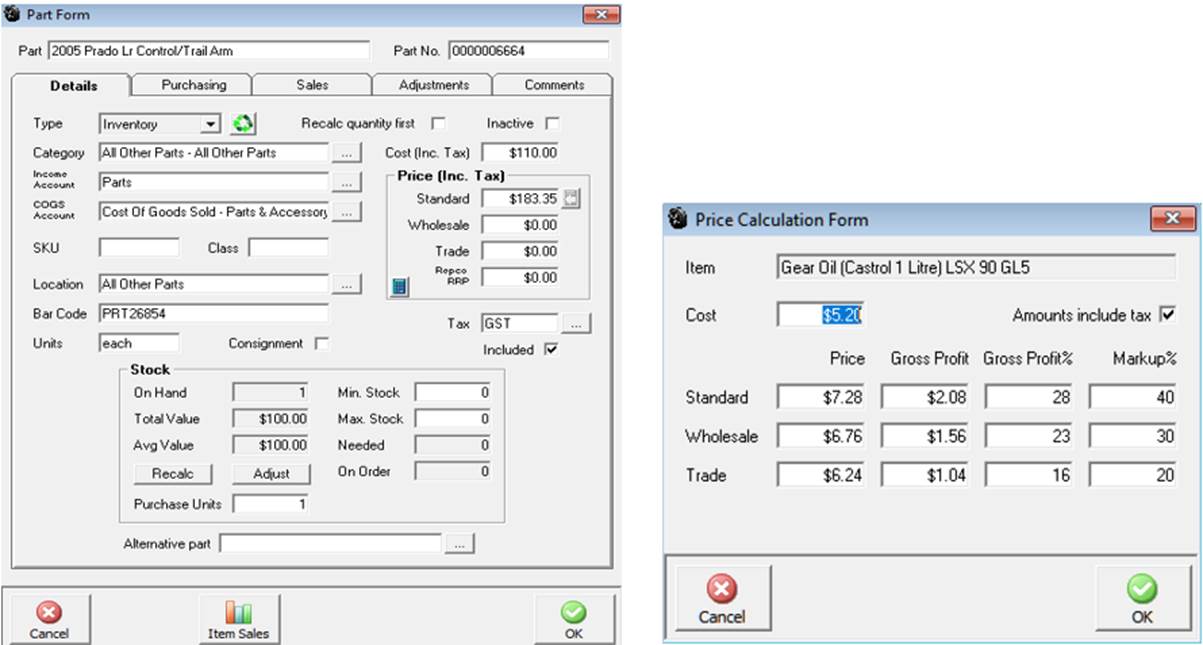

Using

the Calculator is an easy way to calculate gross profit or markup margins

for retail, wholesale and trade prices.

Part

Form, Calculate function: Allows

you to automatically calculate selling prices and or profit margins including

or excluding tax based on cost or percentage. Enter one value into the

price, gross profit, gross profit% or markup field press tab and all fields

will be calculated. The form defaults to include tax, if you wish to exclude

de-select the amounts included in the tax cell.

Part

Form, Fields:

Consist of the following:

Part:

Enter

the part description

Part

No.

Manufacturer’s part number

Type:Include: Each

has unique use within the system.

Catalog:

Assigned

to items that have no stock control. Note: Automation Premium is

based on double entry accounting principles; as such it is not possible

to record single sided entries. The chart of accounts contains a default

non-inventory purchases other current asset which records the cost

of all catalogue items, the operator will have to transfer funds from

this account to compensate for the cost of these items.

Inventory:

Stock

levels are recorded for inventory items, values are posted to current

assets as inventory on hand. It is also possible to raise purchase orders

for inventory items and receive items through the purchasing function.

Buy-In:

Special

category of inventory item relating to parts that are purchased for individual

jobs or invoices.

Other:

This

option is used to classify expenses and other transactions ie: Telephone,

accounting, rent etc.

Category:

Ability

to assign an item to a category, selecting the button to the right of

the field displays a list, highlight the entry required and select OK

(F12) from the bottom of the category list will insert the category to

the part form.

Income

Account: Selecting

the button to the right allows for the posting of sales to another income

account. Default income account is parts unless you wish to track income

separately for this item it is not necessary to change the posting.

COGS

Account: The default

for all parts is Cost Of Goods Sold, however new COGS accounts can be

attached to individual parts by selecting the button to the right of the

field, creating a new account and attaching the selection to the form.

SKU:

Stock

look up reference

Class:

Gives

the operator the ability to enter classes for specific items

Location:

Allows

you to record the location of a particular item, ie: Shelf 1, Bin 44 etc.

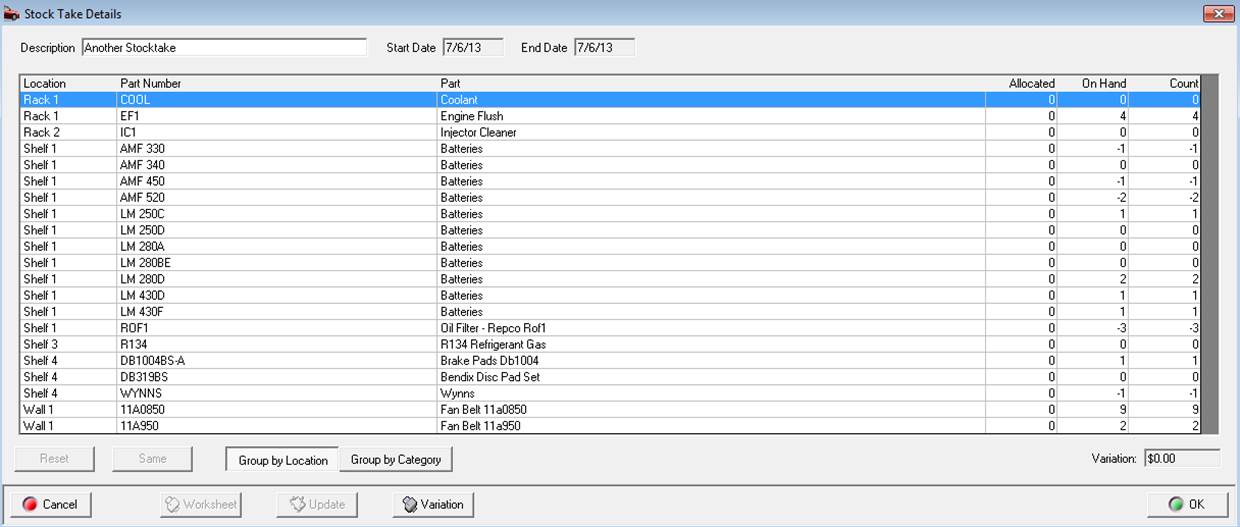

Automation Premium allows for stock takes to be performed by item location.

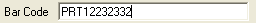

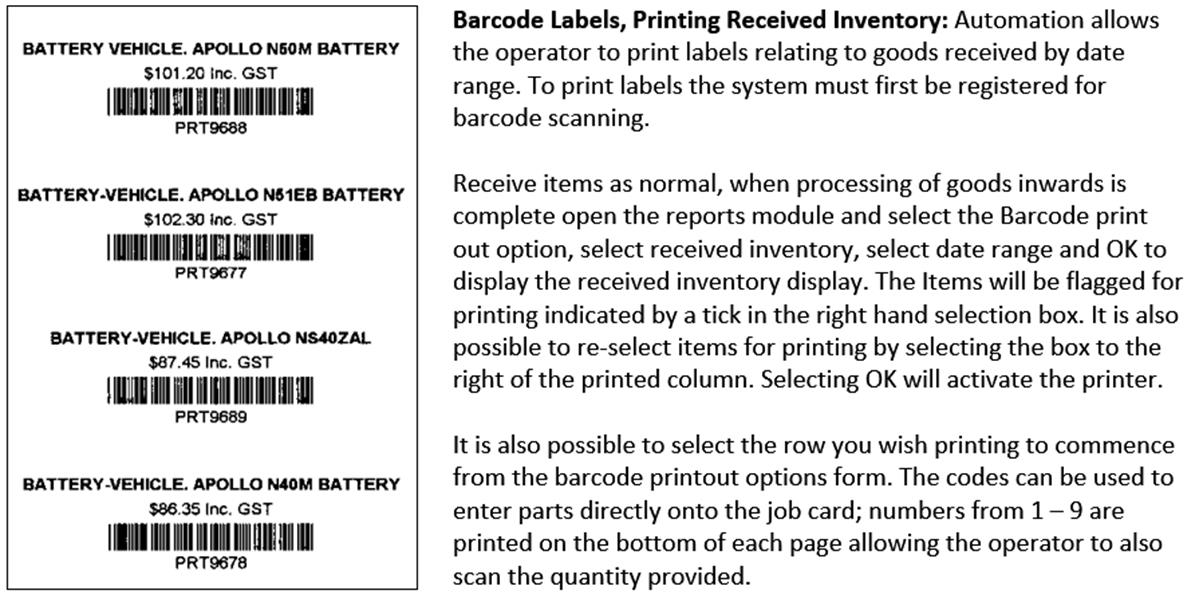

Bar

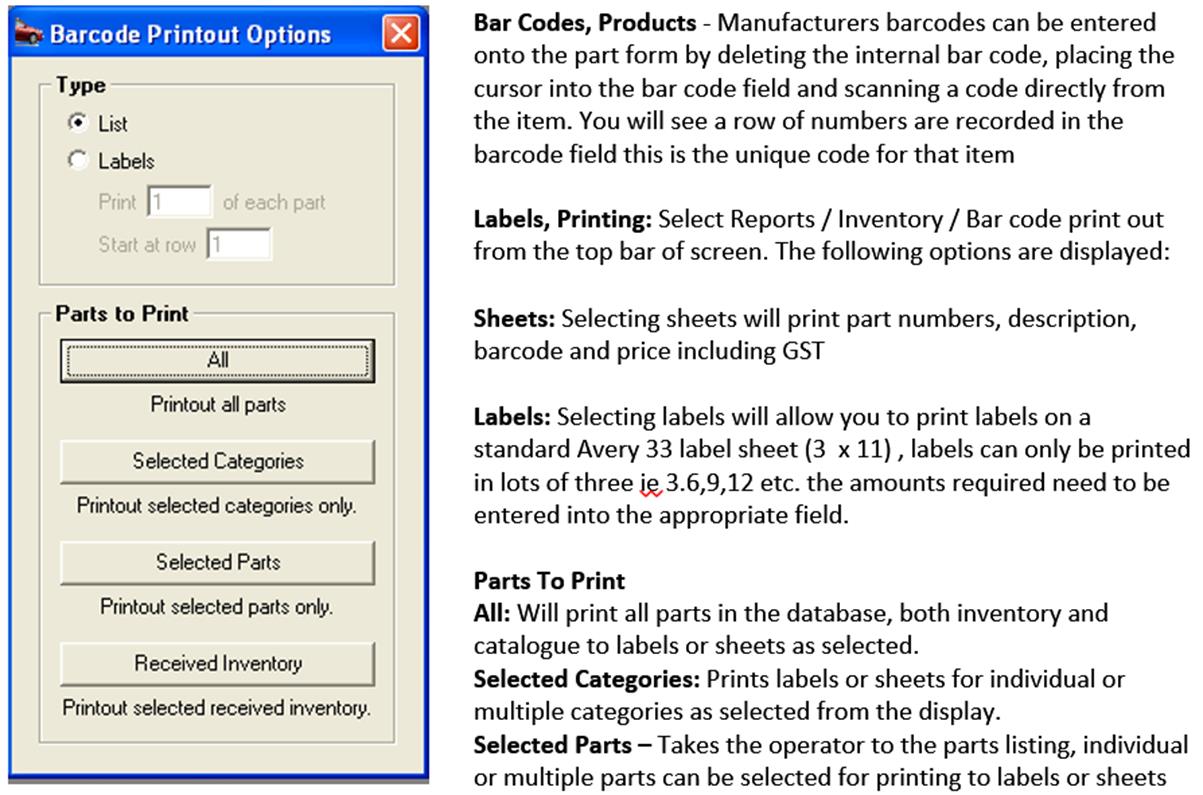

Code: Automation

generates a default bar code when the module is registered for use. Alternatively

manufacturer’s bar codes can be scanned directly into this field. Addition

of a hand scanner allows for items to be scanned directly onto the job

card or invoice.

Units:

Defaults

to each, however this is a free typing field and is easily customised

ie: Litre, pair etc.

Hidden:

Select

if you wish to no longer include the item in the parts list.

Cost:

What

you paid for the item (based on unit cost).

Price:

Standard,

wholesale, trade Automation allows you to record three price levels.

Tax:

Displays

default tax code, selecting the right hand button allow for entry of a

new tax code.

Included:

Default

is tax included this can be de-selected to present data excluding tax.

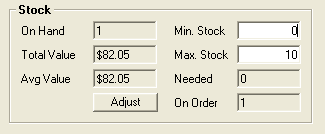

Min.

Stock: Enter

the minimum quantity you wish to carry on hand

Max.

Stock: Enter

the maximum quantity you wish to stock

Alternative

Part: If

you wish to use an alternate when this item is out of stock select the

button to the right of the alternative part field and select the item

from your parts list, click OK (F12) from the bottom of the parts display

and the part number is entered into the field.

Quantity

First Calculation: This

option t when set to true will divide the retail price into the total

for the line item and record the quantity sold rather than changing the

unit price of the item. Example: Part Retail $1.45 item is entered

onto an invoice operator changes the total value to $14.50 the quantity

sold = 10 which is displayed on the invoice / job form.

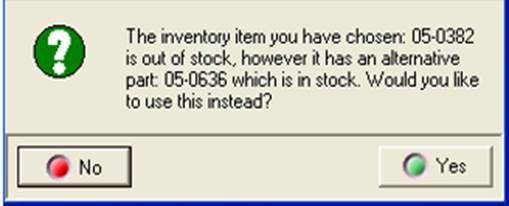

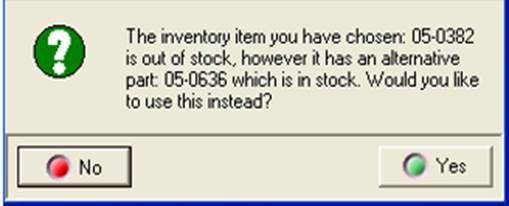

If

you apply an inventory item to a job or invoice that has an alternate

part attached and the selection is out of stock although there is stock

of the alternate part on hand a prompt will advise you to apply the alternate

part. Selecting no will paste the original selection to the job card /

invoice

When

creating a catalogue item ensure the type box contains the catalog selection,

when all fields are complete select OK (F12) from the bottom of the part

form to save.

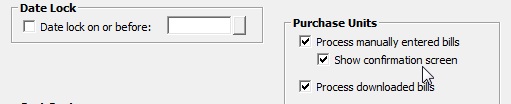

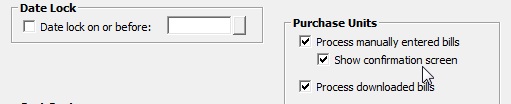

Unit

Purchases, Site Settings: To

enable this feature you need to access the switches in site settings.

Select File / Site Settings / Database Settings over on the right hand

side of the display you will see a purchase unit option, select process

manually entered bills, if you are using Repco invoice retrieval tick

process downloaded bills, if you wish to be prompted select the show confirmation

screen. Save your site settings with OK (F12).

Unit

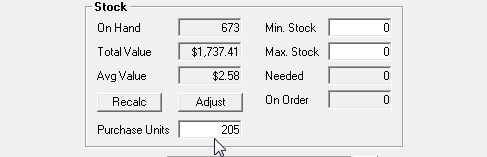

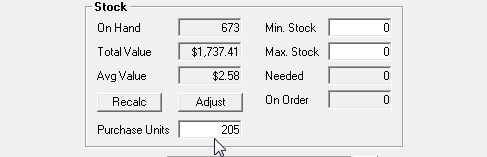

Purchases, Part Form: once

your parameters are set in site setting you will need to open the part

form for the item you wish the calculation to apply to.

Move

down to the field below stock and enter you purchase units into the purchase

units field, save your changes with OK (F12).

Unit

Purchases, Applying The Formula: On

your supplier bill leave the quantity as 1 and change the total price

to the cost of the 1 unit (i.e. 205 litres oil) on completing the 1 x

unit purchase price a confirmation screen will display your reseller unit

value, selecting OK will now divide the unit price by the resell units

entering 205 units @ 2.73 plus tax (in this example), the profit checker

will still compare previous cost to new cost and display a percentage

change which you can accept or decline.

Parts

Listing, Displaying Hidden Parts: Point

at the show hidden tick box located at the bottom of the list and mouse

click. Only hidden parts will be displayed. If you wish to display a part

that has been previously hidden, highlight the item and select edit, point

at the hidden selection and mouse click save you selection by selecting

OK(F12).

Parts

Comments Tab:

A

text area where you can enter notes relating to the supplier, when text

is entered a note it icon is displayed at the end of the line in the supplier

listing clicking on the icon will display text entered in the field

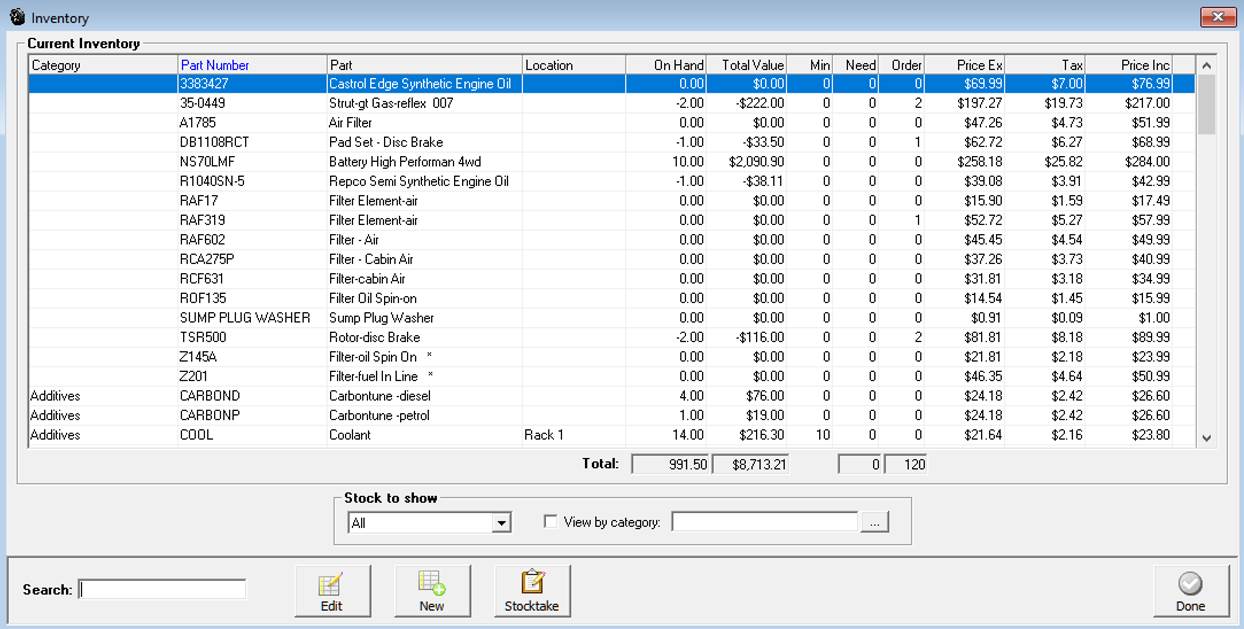

Inventory

Items, Viewing Listing:

Inventory

can be viewed from the parts listing or by selecting Activities / Inventory

from the top menu bar. The inventory screen provides filtering of records

Inventory

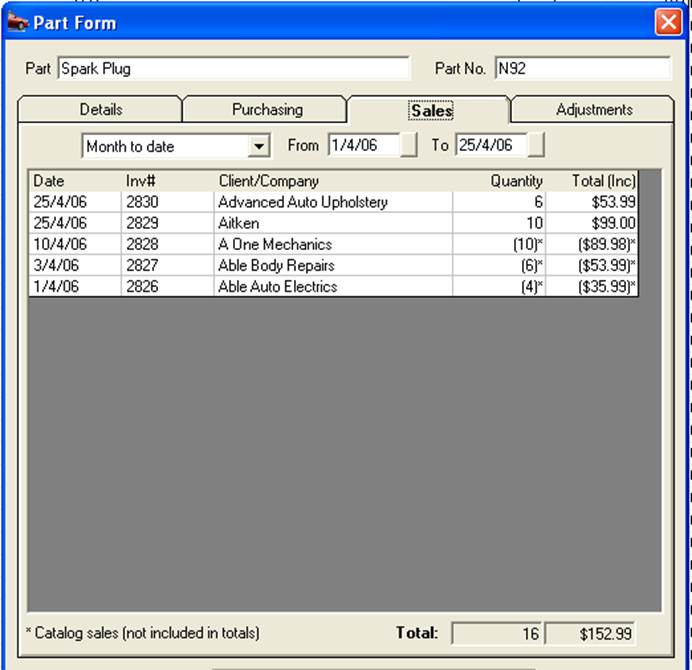

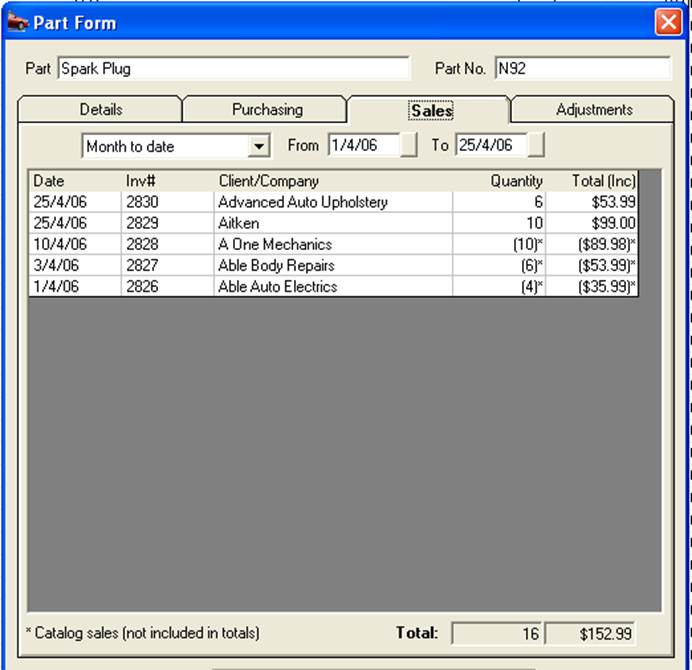

History, Filtering: The

history display allows the operator to view transactions over a specified

date range or period. To view by period select the button to the right

of the field displaying month to date, point and click on the period required

from the drop down menu. The data may take a few seconds to load if there

are lots of transactions. Alternatively a specific date range

can be entered in the from / to date field at the top of the display.

Dollar values include tax. It is possible to drill down to the invoice

or job card from the sales list by pointing and clicking on the transaction.

To drill down to the supplier’s bill, click on the purchasing tab – point

and double click on the line open, the bill is in view. Note: Catalogue

items are not included in the sales totals; they are however displayed

in brackets flagged with an asterisk.

Inventory

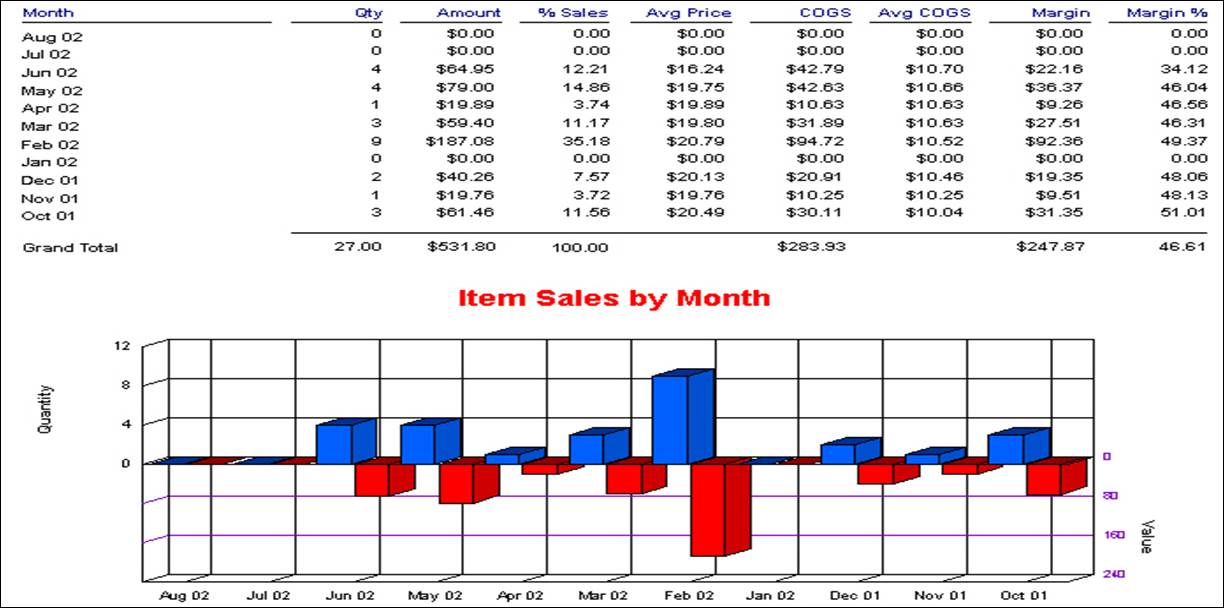

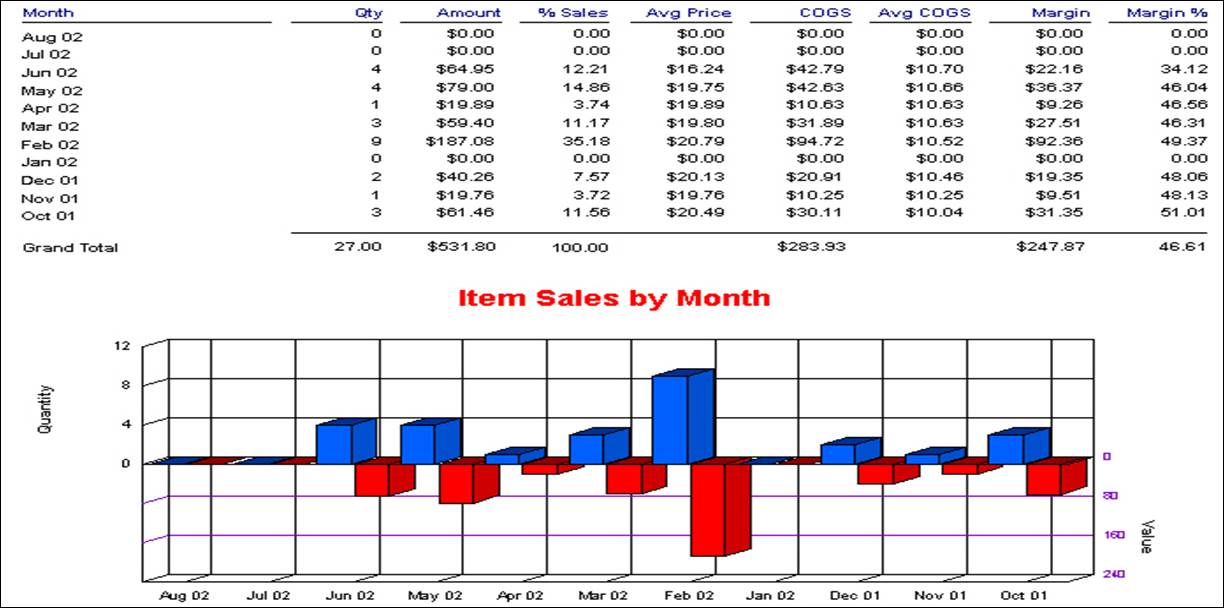

History, Item Sales: From

the part form you can view the sales performance of an item over the past

12 months in both statistical and graphic formats. To run this report

select Item sales from the bottom of the part form.

Selecting this icon from the bottom

of the form displays the last 12 months sales data

Selecting this icon from the bottom

of the form displays the last 12 months sales data

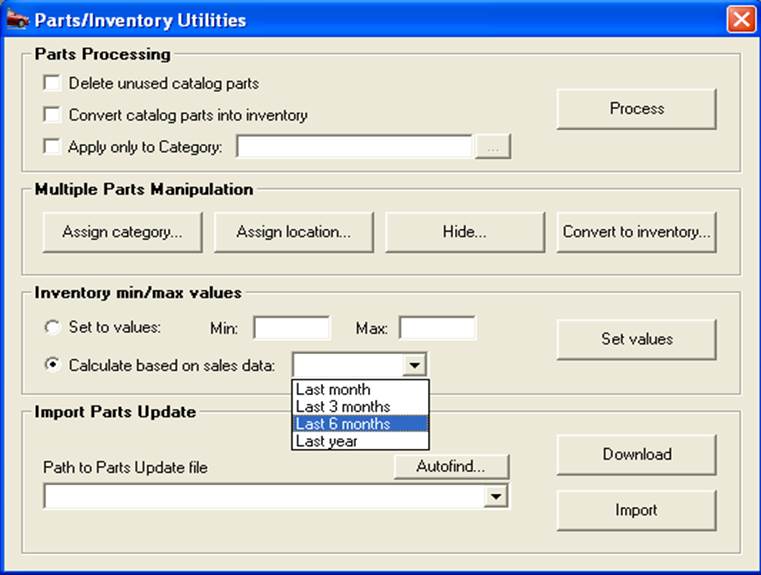

The

parts / inventory utility allows the operator to delete unwanted parts

from the listing and convert remaining parts to inventory either globally

or by category. There is also an option that allows for the

Import

of parts from either the working directory C:\Program Automation Client,

alternate drive or the internet.

Inventory

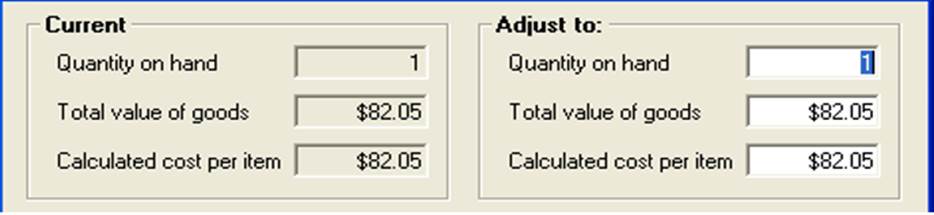

Utility, Parts Processing:

To

access the parts / inventory utility select Activities / Parts & Inventory

Utility from the top of the screen. The utility is now in view, from this

screen the operator can perform the following:

1) Delete

unused parts

2) Convert

non-inventory parts to inventory

3) Select

either function by category

4) Calculate

Minimums and maximum stock holdings

5) Import

a parts update file

Deleting

Unused Parts:

Point

and flag the delete unused parts box, to delete all unused parts select

process. If you only wish to delete specific items these can be selected

by flagging apply to category box and choosing a category. It is only

possible to choose one category per process, select OK from the category

display and select process from the utility screen. Note:

The data cannot be recovered; items already used will remain in the parts

listing

Inventory

Utility, Converting Parts to Inventory:

Point

and flag the convert non-inventory into inventory, to make all parts inventory

select process. If you only wish to add specific items these can be selected

by flagging the apply to category box and choosing a category. It is only

possible to choose one category per process, select OK from the category

display, and select process from the utility screen. Note:

Inventory and buy-ins cannot be deleted from the database, they can however

be hidden from view by selecting the hidden option on the part form.

Inventory

Utility, Apply Changes to a Category:

Allows the operator to apply any of the

above processes to one category only.

Assign

Category To Parts: This

utility allows the operator to assign multiple parts to a category. Select

assign category to parts, the category listing is in view. Select the

category you wish to assign, confirm with OK, from the parts listing highlight

the items you wish to assign and press the enter key or select OK to flag

items in the parts listing. Once all items to be assigned are flagged

select OK to complete the task a message box will confirm the process

has been successful.

Remove

Parts From Parts Pick List:

To

maintain data integrity Automation Premium does not allow for deletion

from the parts listing of items allocated to jobs. However this feature

allows the operator to no longer display unwanted items in the parts listing.

To remove items select the option and flag items for removal from the

parts listing and confirm with OK.

Assign

Location: Use this

option to assign stock locations to individual parts. To assign locations

to items select the option and flag single or multiple items from the

parts listing and confirm with OK.

Convert

To Inventory: Select

this option to convert catalogue items to inventory, single or multiple

items from the parts listing and confirm with OK

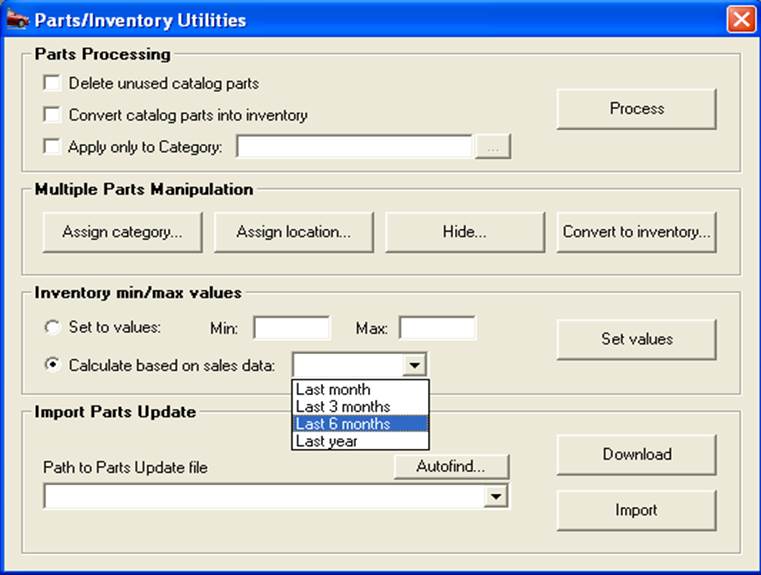

This

feature allows you to set the minimum and maximum quantities for inventory

items in 2 ways

1) Manually

–

Enter the minimum and maximum values to be applied to all inventory items

2) Calculate

Based On Sales – Select

the period from the drop down menu you wish to use to calculate the min

/ max quantities. Automation will calculate the average monthly sales

of each inventory item. The monthly sales volume will be entered into

the maximum field a corresponding value of 50% of the maximum value will

be placed into the minimum field.

To

re-calculate the values select the set values option from the Parts /

Inventory Utility

Download:

This

function allows for updating of the parts file from the Microbase FTP

server, the price file directory is set in the control variables. This

setting will vary between organisations and individual users. To update

the price file via Internet select download, from the parts update screen

select download now. You will now be connected to the server via your

Internet server; the required file will be imported into your program

updating your price file.

Import:

Parts

listings can be imported via the parts update function. Copy the Parts.Mdb

file into the working directory or a floppy disk, select auto find. The

file name and location is displayed in the path to parts update file field,

select import to append the parts file.

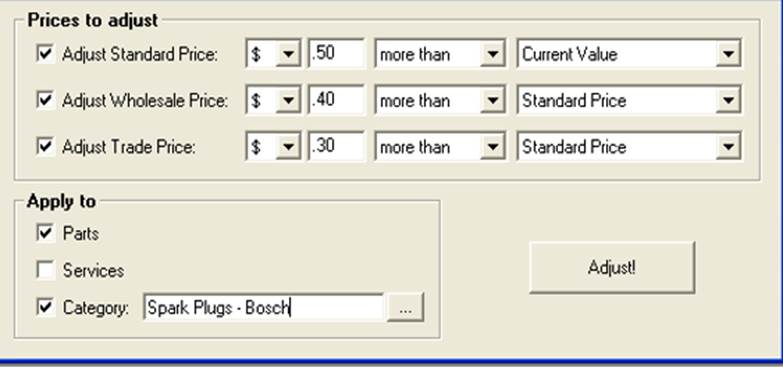

The

pricing utility allows you to change prices by category or sub category

for catalogue, inventory and services. Options allow

for the input of three price point changes standard, trade and wholesale.

Trade and wholesale can be based on either of the other price points or

cost price of the item.

Essentially

using the pricing utility will save time when updating price points and

allows the operator to determine trade and wholesale rates by using any

of the three prices already recorded. Price changes can be entered as

either a percentage or dollar amount.

Price

Utility, Accessing:

To

access the utility select Activities / Pricing utility from the top menu

bar. The display comprises of two sections:

1) Prices

to adjust

2) Apply

to

Price

Utility, Applying price points by dollar value:

To

change prices by a dollar value select the button to the right hand side

of the % field from the pick list select the $ sign, this will now be

displayed in the box to the left. Repeat this for each price point you

wish to change. Enter the values into the second column, select the price

point by flagging adjust Standard, adjust Trade and adjust wholesale.

Price

Utility, Applying price points by percentage:

At

the pricing utility display enter the percentage increase into the first

column, indicate which price points you wish to change. Select less than

/ more than from the pick lists in the third column, next select the value

on which the price changes will apply in the fourth column. Finally you

need to indicate which class or class / category the price changes are

to be applied to. You can select a category / sub category from the prick

list at the bottom of the form. If you are changing prices for a specific

category flag parts, to apply a global change to all parts select parts

only and not category. The same formula applies to services. To execute

select the adjust button on the bottom left hand side of the display.

Price

Utility, Applying Prices Based on Cost: The

utility also allows you to calculate retail, wholesale and trade-selling

prices based on cost. To adjust prices for a category or class select

cost price from the drop down menu. Enter the markup percentage (excluding

tax) or dollar value into each price field, select the category and /

or class and click on the adjust button.

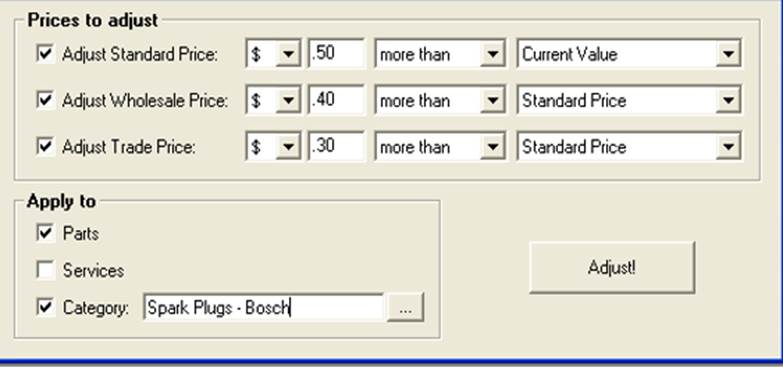

Example

1.0

Price

Point Changes:Standard,

Trade, Wholesale

Amount:

.50

Standard, .40 Trade, .30 Wholesale

Increase

/ Decrease:Increase

Changes

based on:Standard

– Current value / Trade and wholesale on standard price

Applied

to: Parts,

spark plugs / Bosch spark plugs

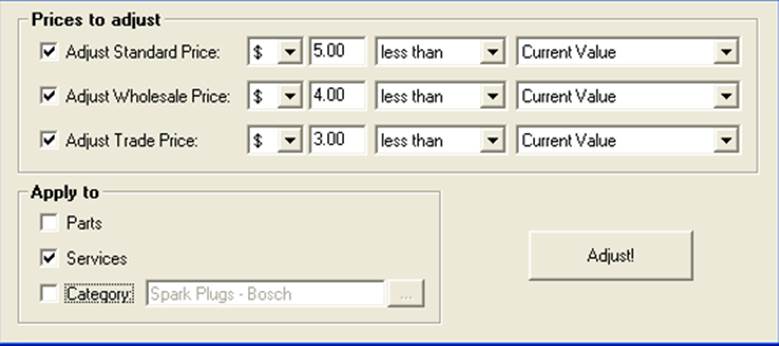

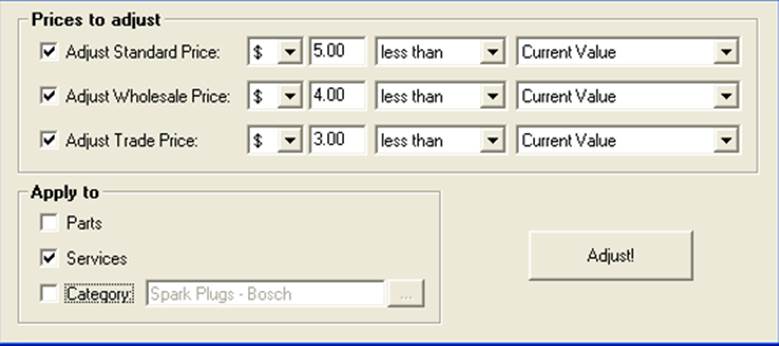

Price

Point Changes:Standard,

Trade, Wholesale

Amount:

$5.00

Standard, $4.00 Trade, $3.00 Wholesale

Increase

/ Decrease:Decrease

Changes

based on:Standard,

Trade and wholesale

Applied

to: All

services

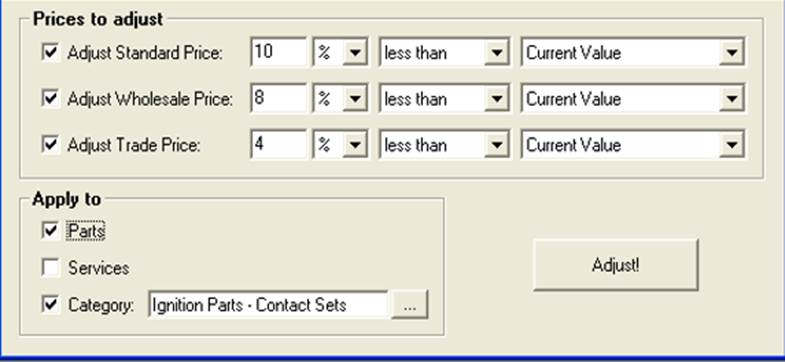

Example

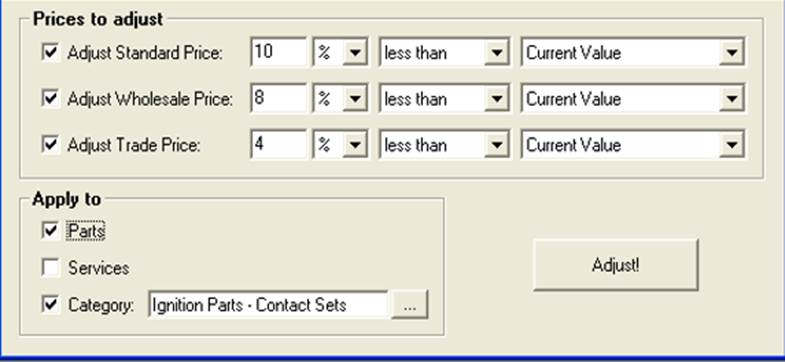

3.0

Price

Point Changes:Standard,

Trade, Wholesale

Amount:

10%

Standard, 8% Trade, 4% Wholesale

Increase

/ Decrease:Decrease

Changes

based on:Standard

– Current value, Trade and wholesale – Standard Price

Applied

to: Parts

– Category Ignition parts / Contact sets

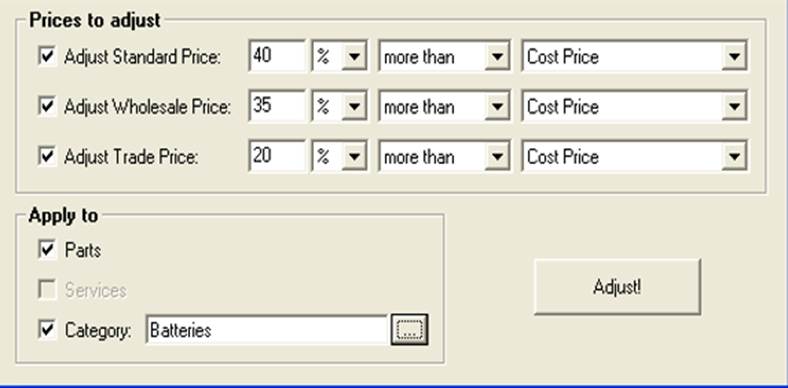

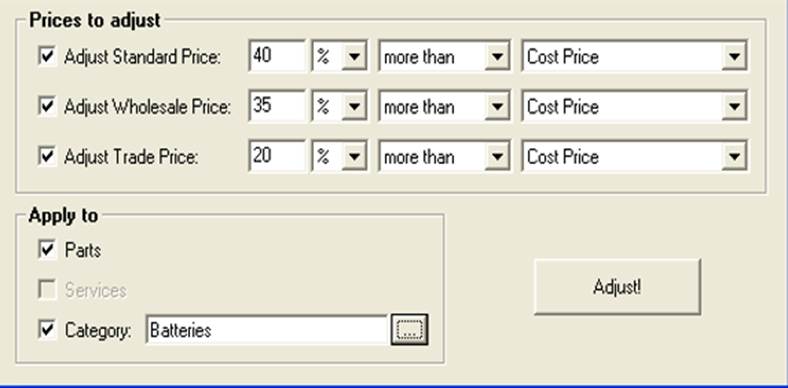

Example

4.0

Price

Point Changes:Standard,

Trade, Wholesale

Amount:

40%

Standard, 35% Wholesale, 20% Trade

Increase

/ Decrease:Increase

Changes

based on: Cost price

of items assigned to the batteries category.

Applied

to: Batteries

Price

Points, Viewing: Price

points can be viewed from the part or service form, it is also possible

to edit individual parts or services from these displays.

Overview:

Automation

allows the user to rebuild an item from current inventory or as a buy-in,

the rebuilt item is then held in stock for sale in the same way as inventory.

Labour can be added to the rebuilt item, the cost of the item is the total

value of labour (at retail rate) plus the cost of the items. Gross profit

on these items is calculated by subtracting the cost (parts & labour)

from the sell price. Rebuilt items will be displayed in the inventory

valuation report in the same way as normal inventory. Parts and labour

used to create a rebuilt item can be copied to a new form if required.

Rebuilt

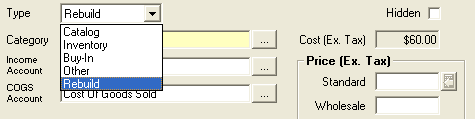

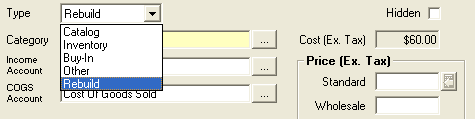

Parts, Creating:

To create a rebuilt part select the parts listing, from the bottom of

the display select new (Insert) from the type field drop down menu select

rebuild

The

format of the part form will now change to allow for the addition of labour

and inventory items

To

add labour point and click in the quantity field and change the value,

you can also edit the hourly charge by clicking in the cost field and

overtyping the standard rate displayed. It is also possible to allocate

the charged labour to a single or multiple technicians by selecting the

labour option located under the rebuild labour & parts section of

the part form. Select the add option to add inventory items to the rebuild.

Note: Only inventory items can be added to a rebuild, if

you are buying parts in specifically for a rebuild item purchase them

as inventory then add them to the rebuild.

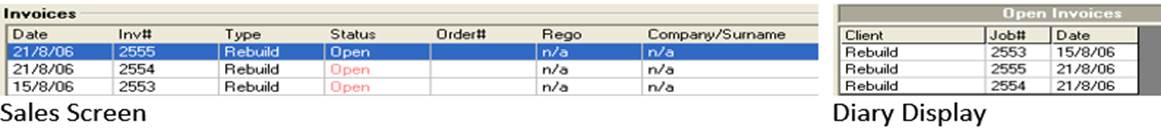

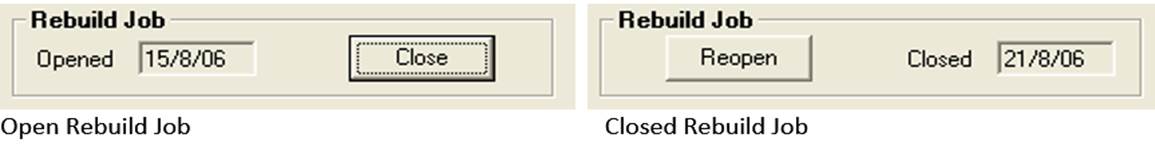

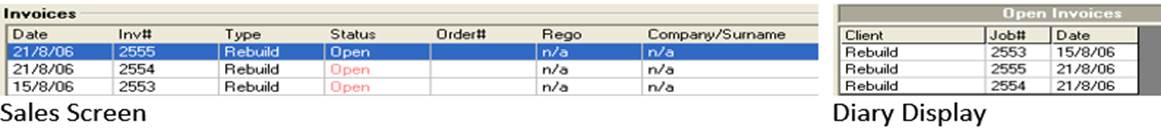

Rebuilds

can be held open the same as charge and vehicle invoices, access to open

rebuilds is available from both the diary (in week view) and the sales

screen. You can also open a rebuild job from the parts listing by pointing

and clicking on the line item.

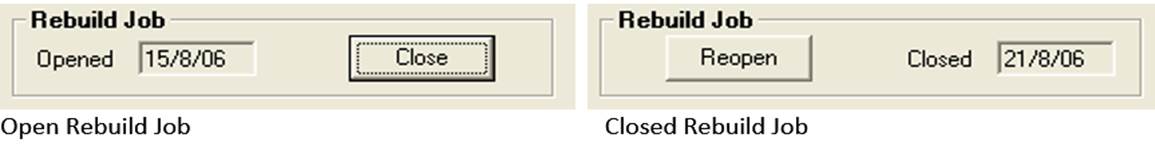

The

quantity of parts added to rebuilds are recorded in the allocation column

of the parts listing, when a rebuild item is completed it must be closed

using the close option located above the labour and parts grid of the

part form. When a rebuild job is closed the inventory items are subtracted

from the stock on hand.

The

cost of a rebuilt item is determined by the cost of the inventory items

and labour value added to the part. The rebuild item can be priced in

the same way as inventory items, the gross profit on an item is calculated

by subtracting the cost from the retail / wholesale or trade sell excluding

GST. To close a rebuild select the close option from the rebuild form.

Rebuilds,

Re-Opening and deleting:

Rebuilt parts that require editing can be re-opened the same as job cards,

to reopen a rebuilt job item go to the part form click on re-open, confirm

your action by selecting yes from the warning message. Edit the form as

required then re-close by selecting the close option.

To

delete a rebuild the job must be reopened, highlight the item from the

parts listing; select the delete option at the bottom of the list. To

view rebuilds in the parts listing point and click on the rebuild option

at the bottom of the list

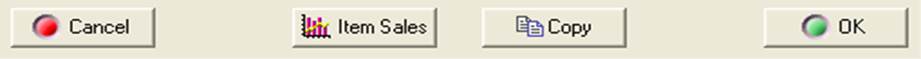

Rebuilds,

Copying Parts & Labour:

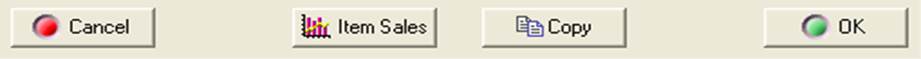

To

copy a rebuild “kit” from a previous job perform the following:

1) Open

a new rebuild item

2) Select

the copy option from the bottom menu bar

3) From

the list of rebuilds highlight the item you wish to copy from

4) Select

the OK (F12) button from the bottom of the parts listing

5) The

parts and labour from the highlighted item have been copied to the new

rebuild

Use

the copy option to copy parts and labour between rebuilds

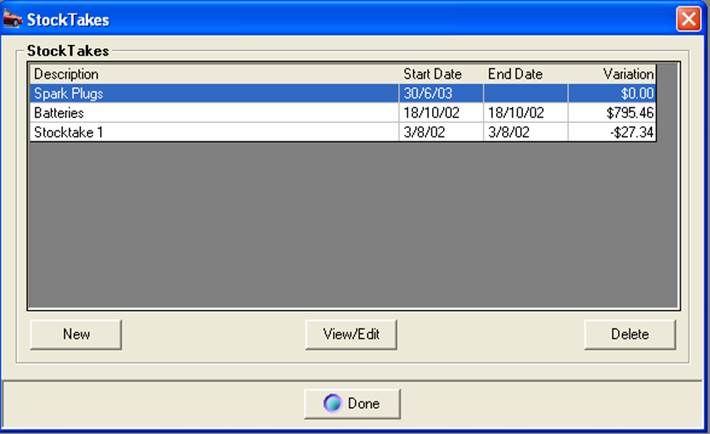

Inventory

& Stock Take Reports

Reports,

Inventory Accessing:

Select

Reports / Inventory from the top menu bar, available reports include:

Inventory

Valuation Summary

Inventory

Stock Status

Reorder

Report

Price

List

Reports,

Inventory Valuation Summary: This

report displays stock on hand by category, if you wish to show all categories

select all, to select a single or multiple categories choose selective.

Selective allows you to tick the categories required; all will print all

categories. The information contained in this report gives you a detailed

view of stock on hand with sub totals for each category choice and a grand

total of all columns.

Reports,

Inventory Stock Status: Allows

you to view quantities of stock on hand plus minimum stocks, quantities

required for jobs and items on order. The last supplier is also displayed

in the preferred supplier column.

Reorder

Report:

Provides

a list of items by supplier that are below minimum, suggesting quantities

that bring levels back up to maximum.

Price

List: Prints

a price list of parts by category including Tax if applicable.

Overview:

Automation

allows you to check the stock of a single item on hand at other nominated

sites (Remote Group) directly from the local parts listing. For this feature

to work both local and remote machines must be connected to the internet

(Broadband Preferred). All sites in the group must have performed a replication

to the Microbase server, and finally the option must be selected in settings

/ Configuration.

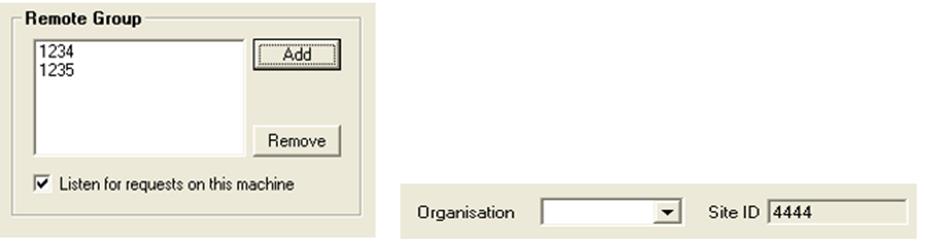

Set-Up:

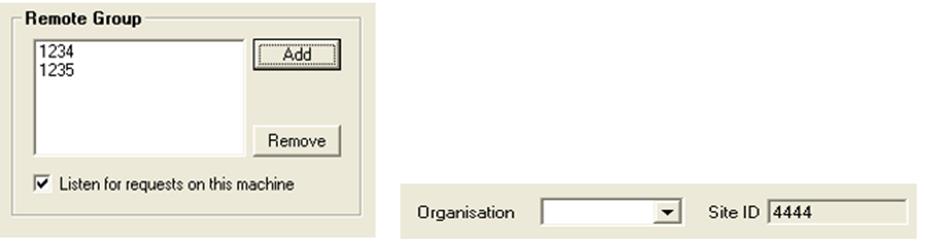

1.

Ensure your site is set-up with a unique identifier – Microbase personnel

will perform this for you on installation, you can check your site id.

In File / Settings.

2. To

set-up the sites you wish to communicate with select add from the remote

group section of the form. Enter the unique site id, finally ensure that

one of the machines (if you are on a network) has the listen for requests

option selected. The machine MUST have access to the internet.

If you wish to remove a location highlight the site id. And click on remove

3.

Save the new settings with OK (F12)

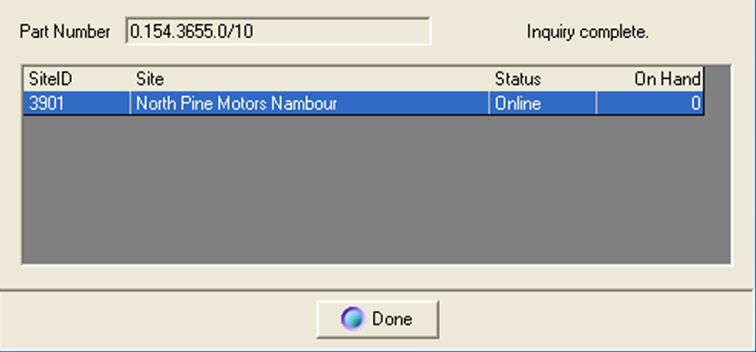

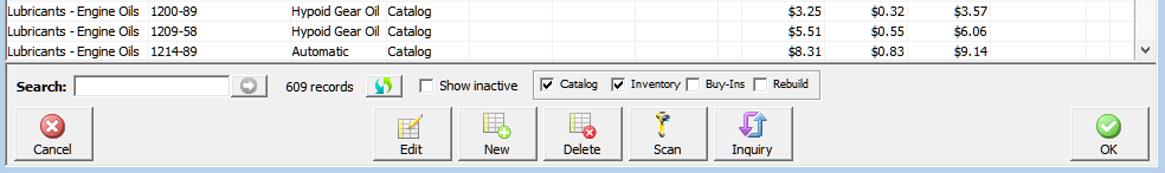

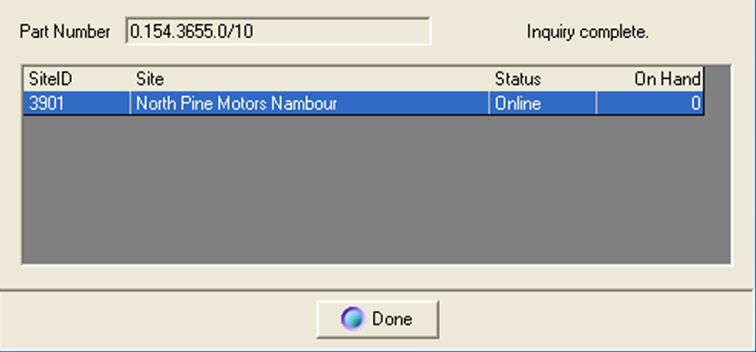

Performing

A Parts Inquiry

Parts

inquiries are performed from the parts listing, select the item you wish

to run an inquiry for and mouse click on the inquiry button located at

the bottom of the parts listing.

Your

site will now communicate via your internet connection with the other

sites in your group and display the stock available. If a site in the

group is not connected to the internet the status field will display an

off line message.

The

results of your query will be returned within 5 – 10 seconds (depending

on the speed of your internet connection) If you are querying multiple

locations the quantities on hand will be listed for each site. To cancel

the task select done from the bottom of the part inquiry form

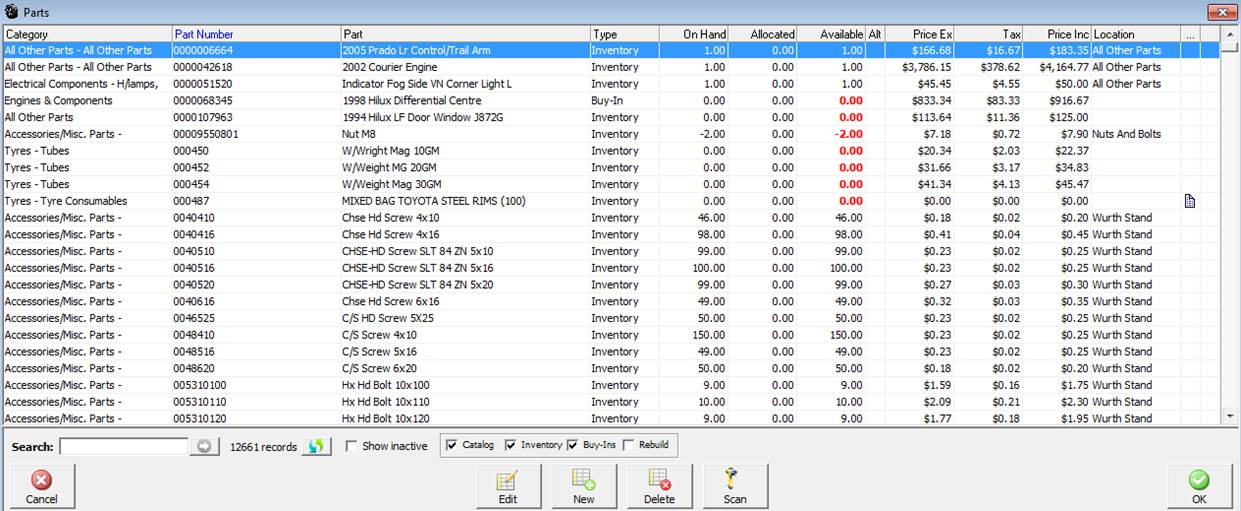

Select

this button from the top of the screen to view the parts listing, alternatively

select Lists/Parts. The parts listing can also be opened from the job

card, invoice or service form. The display includes an allocated and available

field, the values displayed relate to inventory items only. Allocated

quantities record the total items allocated to open jobs, invoices or

cash sales.

Select

this button from the top of the screen to view the parts listing, alternatively

select Lists/Parts. The parts listing can also be opened from the job

card, invoice or service form. The display includes an allocated and available

field, the values displayed relate to inventory items only. Allocated

quantities record the total items allocated to open jobs, invoices or

cash sales.

Selecting this icon from the bottom

of the form displays the last 12 months sales data

Selecting this icon from the bottom

of the form displays the last 12 months sales data